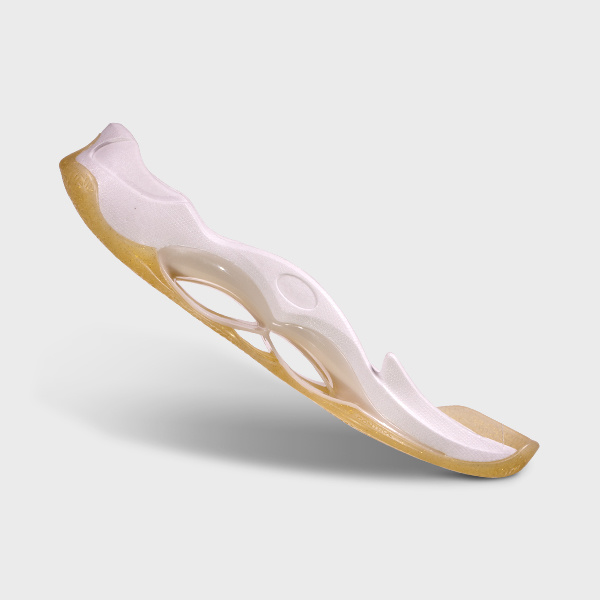

Product display

-

One-piece Moulding Process

Mold design, opening,,difficulty of production hasbeen all-side improved, integrated molding threeopening mold process has created the industry first!the special process of the isomerism cannot bemanually fitting,No risk of yellowing after fitting,and a number of runway model designs have beencompleted in technical innovation, and achievingbreakthrough achievement inperformance,aesthetics,and efficiency -

Popcorn Traceless Process

The appearance is fine and non-granular,lightweight structure and shock absorption material which makes running more efficiency -

Side Wall Coating Process Of Popcorn Sole

Enrich the texture of pattern, more fine line sense and property, subvert the traditional new process. anti-fouling and dust-proof, easy to clean and more durable to protect the traditional popcorn particles, the more prominent of the appearance process & beauty. -

Regular Model

The original process requires manual fitting of theupper layer, lower layer,carbon fiber plate (TPU)and the adhesive solution.special process of isomerism can not be fitting bymanua. -

Pet Toys

The pet toys produced by our factory using ETPU materials with anti-wear, high elasticity, easy cleaning, and bitten resistance, it is a reassuring material that had beed widely used in the pet supply market, we have developed a various shapes such as Frisbee, bite stick, ball, rugby, etc., which is very popular among consumers.

-

One-piece Moulding Process

Mold design, opening,,difficulty of production hasbeen all-side improved, integrated molding threeopening mold process has created the industry first!the special process of the isomerism cannot bemanually fitting,No risk of yellowing after fitting,and a number of runway model designs have beencompleted in technical innovation, and achievingbreakthrough achievement inperformance,aesthetics,and efficiency -

Popcorn Traceless Process

The appearance is fine and non-granular,lightweight structure and shock absorption material which makes running more efficiency -

Side Wall Coating Process Of Popcorn Sole

Enrich the texture of pattern, more fine line sense and property, subvert the traditional new process. anti-fouling and dust-proof, easy to clean and more durable to protect the traditional popcorn particles, the more prominent of the appearance process & beauty. -

Regular Model

The original process requires manual fitting of theupper layer, lower layer,carbon fiber plate (TPU)and the adhesive solution.special process of isomerism can not be fitting bymanua. -

Pet Toys

The pet toys produced by our factory using ETPU materials with anti-wear, high elasticity, easy cleaning, and bitten resistance, it is a reassuring material that had beed widely used in the pet supply market, we have developed a various shapes such as Frisbee, bite stick, ball, rugby, etc., which is very popular among consumers.

About Us

Tongxinyuan New Material Technology Co., Ltd. was established in 2015, Speciaizing produce in supercritical phisical foaming polymer materials and its application area, which is a high-tech enterprise with research&udevelopment and manufacture.

Our company has inteligent, standardized production lines and self-developed production equipment (annual capacity reach to 1500 milion pairs, serving many well-known domestic brands, we provide a complete set of technical innovation solution for the professional running shoes with lightweight and high elasticity reguirements.

Our company has a complete production chain from the granule of thermoplastic polyurethane (TpU) raw materials to foaming, molding.and finally to the whole outsole assembly, ensuring the company's strong strength in vertical integration,stability and consistency of productquality, and effective cost control, improving production eficiency, and quickly respond to market demand. Ensuring products quality and quickly customization and adjustment according to customerrequirements.

2023 Annual Performance

Annual output of the company

Expansion of the number of companies

Cooperative Products

NEWS

COOPERATION CUSTOMERS